QUALITY CONTROL

Products Inspection

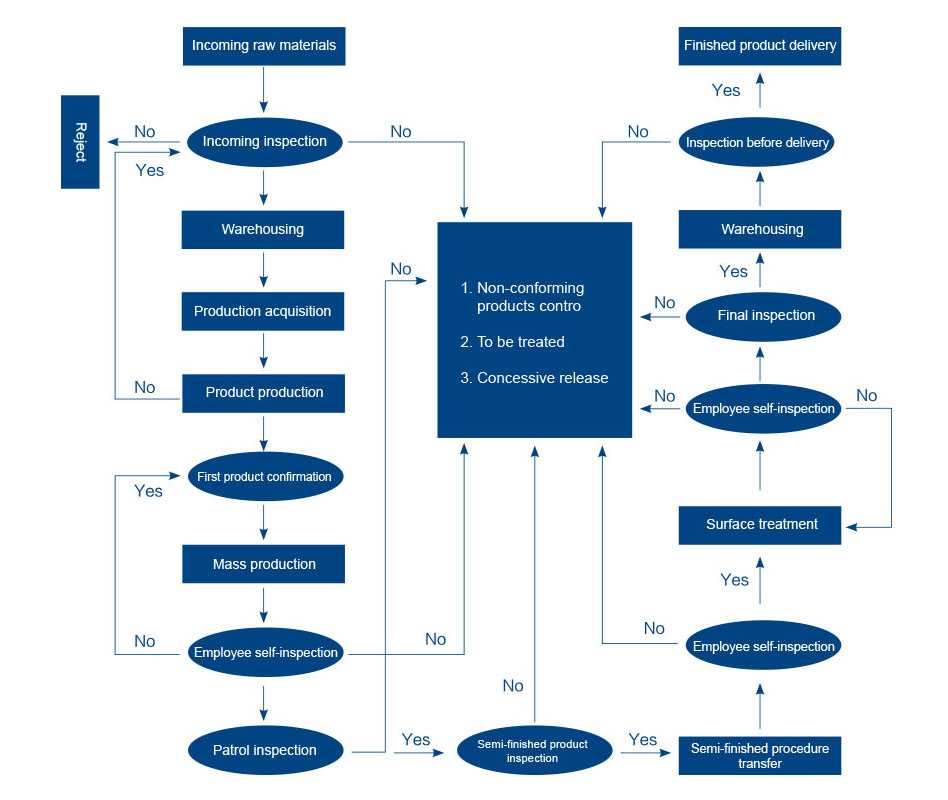

Jumi advocates the enterprise spirit of "people-oriented, user priority". Jumi has established the quality inspection center to inspect the quality during the whole process, thus ensuring the quality and long-term stability of products.The product quality inspection of our company is based on the manufacturing course of the products, including raw materials inspection when purchasing, semi-finished products inspection control, and the final inspection of the finished products.

Jumi adopts "Three-level inspection" system including "self-inspection", "mutual inspection" and "special inspection", so as to ensure the total three-level product quality inspection system that "Non-conforming raw materials are not put into use, non-conforming products are not produced, and unqualifed products are not delivered".

The Quality Inspection Department is provided with quality inspectors of different work procedures, workshop inspectors, raw and auxiliary materials inspectors and finished product inspectors, altogether more than 30 professional quality inspectors.

PRODUCT QUALITY CONTROL FLOW CHART

PROCESS TEST SEQUENCE

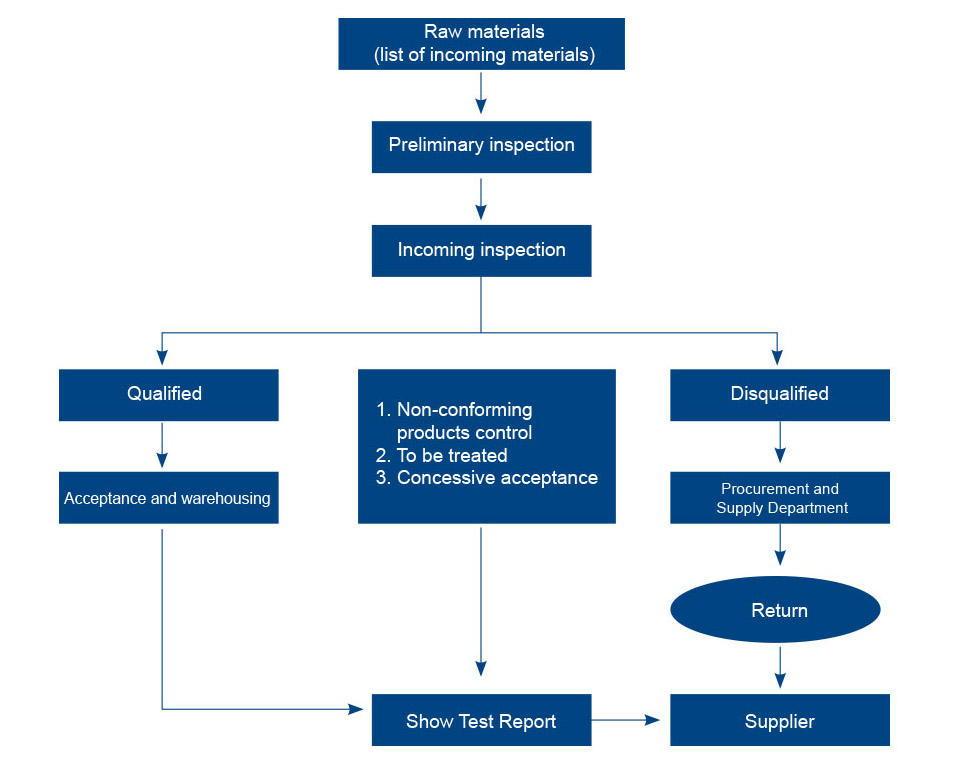

The reasonable setting of process control and quality control points is the key factor to ensure product quality. According to the actual situation, quality inspection control points are set in raw material warehousing, ingot melting and casting, profile extrusion molding, surface treatment, finished product warehousing, product delivery and sequence transfer, etc., and the self-inspection of each production process is combined to ensure that the whole process of product realization is controlled.

*The following briefly describes and illustrates the detection work procedure of some main control points.

Copyright 2009-2022 JUMILUX